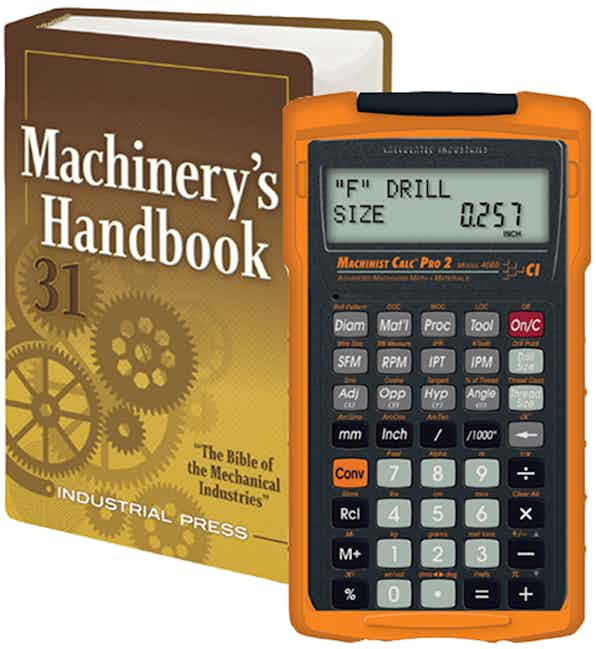

Machinery's Handbook & Calc Pro 2 Combo: Large Print

Thirty-first Edition

Thirty-first Edition

2996 Pages, 7.10 x 10.20 x 4.50 in

- Mixed media product

- ISBN: 9780831142315

- Availability: In Stock

- Publication Date: March 2020

$224.95

BUY